Core Values

We Work H.A.R.D.

Highest Quality

We know quality is paramount in everything we do, this allows us to be proud of our work.

Attention to Detail

We obsess over the details, big or small. Accuracy is the main focus at all times.

Reliability

We rely on our teammates to work together effectively to complete our daily tasks, and to achieve our strategic goals.

Dedication

We are dedicated to professionalism, speed, and efficiency, always exceeding expectations.

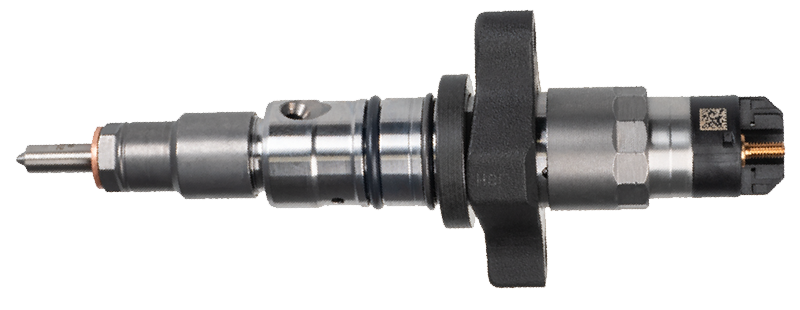

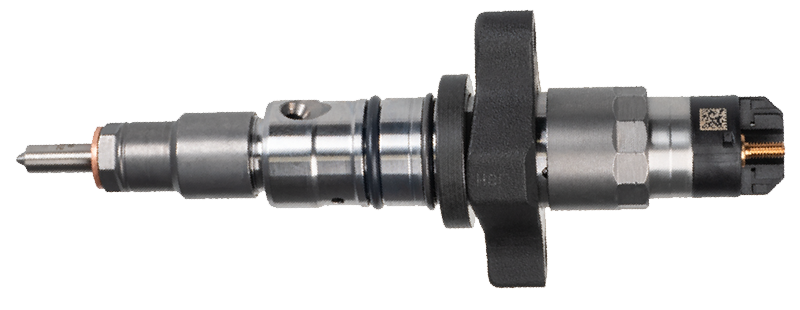

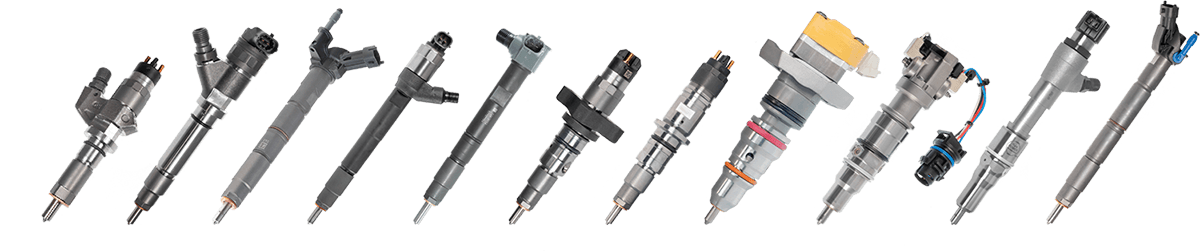

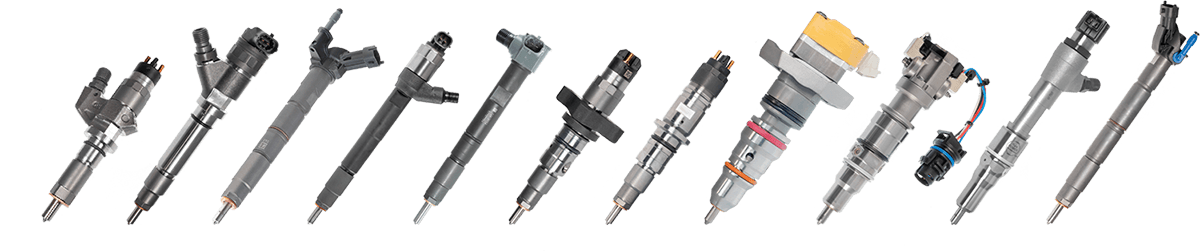

about us

InjectorsDirect.com was founded in San Luis Obispo, California in 2009. After having to replace the injectors in an LB7 Duramax, we realized that there needed to be a better way for diesel pickup owners to get quality fuel injection parts for their trucks at reasonable prices. We offer parts for Duramax, Cummins, and Power Stroke Diesel engines. Our expert technicians are trained to test and service all the products we offer.

Our Facility

InjectorsDirect.com has invested extensively in our state of the art facility, ensuring our ability to provide our customers the parts they need, when they need them.

efficiently designed

Our new facility opened in February 2018 and was designed from the ground up with efficiency in mind, to meet our production needs as well as the needs of our customers.

purpose built

The facility features specialized rooms designed specifically for cleaning, servicing and testing injectors.

innovative technology

We utilize vertical lift modules provide us with efficient automated storage and organization of our extensive inventory.

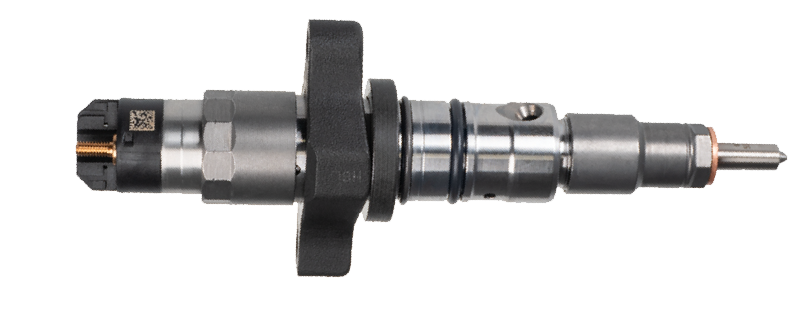

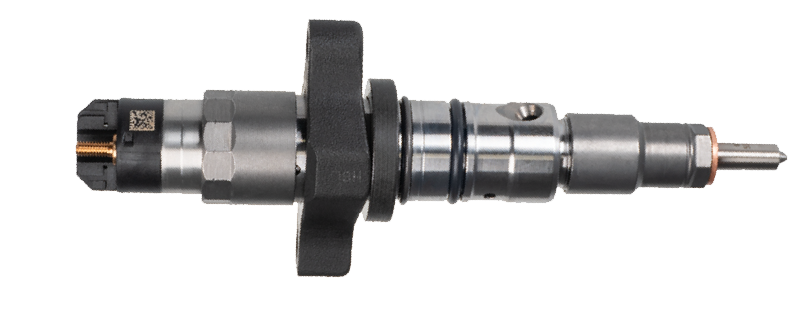

Our equipment

We have the latest and best equipment in order to properly clean, test, and calibrate injectors for Duramax, Cummins, and Power Stroke engines.

Hartridge IFT-70

Single line common rail injector test stands (A.K.A. pop testers). These machines are capable of producing 700 bar (10,000 P.S.I.), and are used to test basic injector functions, roughly check delivery/return ratio (at lower pressures), visually inspect nozzle spray patterns, as well as flush out any residual diesel fuel and other contaminants that may be present in the injectors.

Hartridge IFT-200

Four line computerized common rail injector test stand/flushing rig. The first of it's kind in the US; This machine is capable of 2000 bar (29,000 P.S.I.), and is used to test basic injector functions, roughly check delivery/return ratio (at higher pressures), as well as flush out any residual diesel fuel and other contaminants that may be present in the injectors.

Hartridge CRI-PC 04B-CZ

Four line automated common rail injector test stand with pressurized backleak measurement. This machine is capable of testing all common rail injectors (including the newest generation piezo injectors). This machine is capable of 2000 bar (29,000 P.S.I.), and is used to duplicate the each injector's performance as if it were installed in an engine. It is computer controlled, and fully automated. It is programmed to run very precise and specific tests on each particular injector. These tests are conducted at numerous different pressures and operating conditions (pulse width & I.P.M.). Each test step digitally measures & analyzes the injector's response time, delivery volume, return volume, return pressure, and return temperature. Each test also includes a solenoid coil resistance test to ensure the solenoid is in good condition, as well as a static back leak test to ensure that the injector's internal seals are intact and performing as they should. This machine tells us everything there is to know about each particular injector.

Maktest 1026

Single line common rail injector test stand with electronic measurement. Our first test stand; This machine is capable of 2000 bar (29,000 P.S.I.), and performs a similar operation to our CRI-PC, except it is only capable of testing one injector at a time.

Hartridge HA230 with HJ04

Siemens 6.0L upgrade kit

This four line machine is capable of testing 4 H.E.U.I. injectors simultaneously. It allows us to test basic injector functions, visually check each nozzle's spray pattern as well as delivery volumes at numerous different pressures and operating conditions (pulse width & I.P.M.)